Flexa Systems: Your Industrial Automation Repair Resource

Welcome to the Flexa Systems blog! Here, we share our expertise in industrial automation equipment repair, covering everything from VFDs and HMIs to PLCs and beyond. Stay tuned for insights, tips, and updates on keeping your industrial operations running smoothly.

VFD Repair – Fast Component-Level Drive Repair Service

VFD Repair – Fast, In House, Component Level Professional VFD Repair Services in Texas Flexa Systems provides VFD repair services from our shop in DFW, Texas, serving customers across the USA.. We repair variable frequency drives (VFDs) and frequency drives all the way down to the component level – in our own shop, not outsourced. [...]

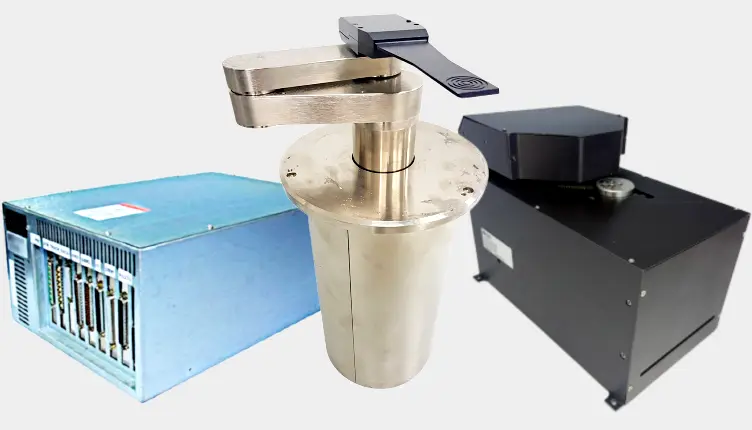

Brooks / PRI / Equipe Controller, Robot & Pre-Aligner Repair Services

We’re pleased to share that Flexa Systems now provides component-level repair for Brooks Automation wafer handling equipment—including legacy PRI and Equipe platforms. Whether it’s a pre-aligner, wafer handling robot arm, or a controller, our engineering team is set up to help you recover fast. Why this matters Brooks wafer handlers have been workhorses in fabs …

Top-Rated Electronic Repair Services for Industrial Equipment – Flexa Systems USA

Industrial Electronic Repair Services Backed by Precision, Experience, and Technology When critical automation equipment breaks down, fast and accurate electronic repair isn’t just a luxury—it’s a necessity. At Flexa Systems, we specialize in high-quality electronic repair services for industrial systems of all sizes, handling everything from basic power faults to complex board-level issues. Why Businesses …

🔧 Expert Component-Level Repairs for TECO FM-50 Series VFDs

At Flexa Systems, we specialize in component-level repair of TECO FM-50 Series VFDs, helping manufacturers reduce downtime and avoid costly replacements. These compact and reliable variable frequency drives are widely used across the electronics manufacturing sector, including in wafer probers, testers, and a wide range of industrial automation lines. ⚠️ Common TECO FM-50 VFD Issues …

The Mysterious Parker MB2 series

The Mysterious Parker MB2 series: A Deep Dive into a Discontinued Mobile VFD The Parker MB2 mobile motor controller is a fascinating piece of engineering, shrouded in a bit of mystery due to its discontinued status and lack of readily available information online. Designed specifically for heavy-duty mobile applications, this robust VFD (Variable Frequency Drive) [...]

Innovation at Its Core: Repairing Beyond Limits with Flexa Systems

Innovation at Its Core: Repairing Beyond Limits with Flexa Systems At Flexa Systems, our commitment to excellence goes beyond conventional repair services. We specialize in repairing electronic devices up to the component level, achieving a remarkable repair rate even in seemingly impossible cases. Our unique approach to repair involves innovation, pushing boundaries, and finding solutions [...]

BGA Chip replacement

BGA components have become ubiquitous in today’s electronic devices, thanks to the ever-increasing integration level of chips. As technology progresses, we now operate on a 5nm technological process, with single integrated transistors 4000 times smaller than those in the 1970s. This evolution has led to the adoption of BGA-type housings (Ball Grid Array), allowing …